Revolutionizing Engine Rebuilds with Select Technology

Select Engine Rebuilds leverages cutting-edge technology and precision engineering for superior engine rebuilding. Using state-of-the-art equipment like CNC machines and 3D printers, they ensure accur…….

Select Engine Rebuilds leverages cutting-edge technology and precision engineering for superior engine rebuilding. Using state-of-the-art equipment like CNC machines and 3D printers, they ensure accurate disassembly, fabrication, and repairs. Their skilled team offers cost-effective solutions with detailed breakdowns, providing high-quality, long-lasting rebuilds that surpass expectations. The modern facility caters to various needs, from standard overhauls with warranties to customized high-performance builds, promoting better fuel economy and reduced environmental impact.

Unleashing revolutionary advancements in engine rebuilding, the industry now boasts state-of-the-art facilities equipped with cutting-edge technology. This transformative journey leverages advanced machinery and meticulous quality assurance processes to restore engines to like-new condition. Discover how these innovations benefit both customers and the industry at large, ensuring superior performance, longevity, and environmental sustainability. Explore the future of engine rebuilding through the lens of Select Engine Rebuilds’ leading practices.

- Advanced Technology in Engine Rebuilding

- State-of-the-Art Equipment and Tools

- Quality Assurance Processes

- Benefits for Customers and Industry

Advanced Technology in Engine Rebuilding

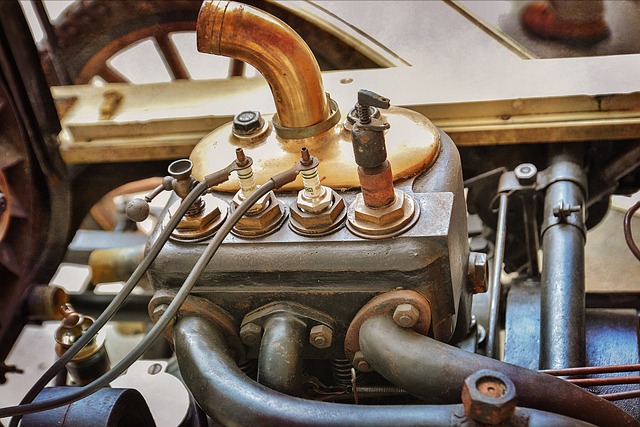

In the realm of engine rebuilding, advanced technology is revolutionizing the way we restore power to our vehicles. Select Engine Rebuilds leverages cutting-edge tools and precision engineering techniques to ensure every component is meticulously refurbished. Our car engine restoration experts employ state-of-the-art equipment, such as laser cutters and computer-aided design (CAD) software, to achieve unparalleled accuracy and consistency in auto engine building.

These innovations allow our experienced engine mechanics to disassemble engines with ease, accurately identify worn or damaged parts, and precisely fabricate replacements if necessary. As a result, we’re able to offer superior quality engine remanufaturing services that meet or exceed the performance of original equipment. Our team of specialists dedicates themselves to staying ahead of industry trends, ensuring our clients receive the best possible service from start to finish.

State-of-the-Art Equipment and Tools

The heart of any state-of-the-art facility for engine rebuilding lies in its cutting-edge equipment and tools, designed to deliver precision and efficiency like never before. Here, advanced machinery such as CNC (Computer Numerical Control) milling machines ensures meticulous component machining, resulting in unparalleled accuracy and consistency. These machines are complemented by sophisticated 3D printers that allow for the rapid prototyping of custom parts, catering to unique vehicle requirements with speed and versatility.

When it comes to engine rebuilding after an accident or due to wear and tear, these facilities employ specialized tools tailored for intricate disassembly and reassembly. This includes hydraulic presses capable of handling massive forces while ensuring safe manipulation of delicate components. Furthermore, advanced diagnostic equipment enables comprehensive assessments, identifying issues that may impact long-lasting engine performance. By combining such technology with skilled craftsmanship, these facilities offer cost-effective solutions, providing a detailed breakdown of the engine rebuild cost to empower customers in making informed decisions.

Quality Assurance Processes

At our state-of-the-art facility, we’ve perfected the art of Select Engine Rebuilds, ensuring that every engine is meticulously restored to its peak performance. Our rigorous Quality Assurance processes are the cornerstone of our reputation as top-rated engine rebuilding shops. We understand that precision and attention to detail are paramount when it comes to enhancing an engine’s capabilities.

Through a combination of advanced diagnostics, customized performance tuning, and meticulous craftsmanship, we achieve not only powerful results but also remarkable gas mileage improvements. Our goal is to offer not just repairs, but transformative experiences that push the boundaries of engine technology. We’re committed to delivering solutions that not only meet but exceed expectations, making us the go-to choice for those seeking unparalleled quality in engine rebuilding services.

Benefits for Customers and Industry

A state-of-the-art facility for engine rebuilding offers customers and the industry as a whole numerous benefits. One of the most significant advantages is the provision of warrantied engine rebuilds, which instills confidence in consumers, assuring them of the quality and durability of the refurbished engines. This reduces the risk associated with purchasing used or rebuilt engines, making it an attractive option for both individual vehicle owners and fleet managers.

Furthermore, such facilities can provide low-cost engine overhauls without compromising on performance, thanks to advanced technologies and streamlined processes. They also offer customized engine solutions, allowing customers to specify their desired output and efficiency levels. This level of customization enables vehicle owners to optimize their vehicles’ performance, contributing to better fuel economy and reduced environmental impact. Additionally, these facilities can handle high-performance engine builds, catering to enthusiasts who demand top-tier power and speed from their machines.

A state-of-the-art facility for engine rebuilding, such as those employing advanced technology, top-tier equipment, and rigorous quality assurance processes, represents a game changer in the automotive industry. Facilities like these, specializing in select engine rebuilds, offer numerous benefits to both customers and the industry at large. By ensuring precision, efficiency, and longevity in engine restorations, they elevate standards of performance and reliability, contributing significantly to sustainability and cost-effectiveness in today’s digital era.