Optimizing Fast Turnaround Engine Rebuilds with Select Tools

Select Engine Rebuilds distinguishes itself in a competitive market by focusing on swift turnaround times for engine rebuilds, catering to both performance enthusiasts and historical vehicle restorers…….

Select Engine Rebuilds distinguishes itself in a competitive market by focusing on swift turnaround times for engine rebuilds, catering to both performance enthusiasts and historical vehicle restorers. They streamline processes using advanced diagnostic tools, precise measurements, lean manufacturing principles, and specialized equipment, ensuring high-quality builds tailored to diverse makes and models.

In today’s competitive automotive landscape, meeting rapid market demands requires swift engine build projects. This article explores the art of achieving fast turnaround times while maintaining quality in select engine rebuilds. We delve into understanding the critical requirements, optimizing processes, and employing innovative tools & techniques to streamline build times. By implementing these strategies, engine builders can efficiently meet customer needs, stay competitive, and ensure satisfactory results.

- Understanding Fast Turnaround Requirements

- Optimizing Engine Rebuild Processes

- Tools and Techniques for Efficient Build Times

Understanding Fast Turnaround Requirements

When it comes to engine build projects, fast turnaround means completing the task swiftly while maintaining top-notch quality. This is particularly crucial in the automotive industry, where time is money, and customers demand quick repairs or modifications. Understanding the specific needs of fast turnaround projects is essential for select engine rebuilds, especially when catering to a niche market of car enthusiasts who appreciate both performance and historical value.

Restoring vintage engines or engaging in custom engine reconstruction requires a unique set of skills and resources. Professional engine rebuilds demand precision and expertise to meet tight deadlines without compromising the integrity of the final product. By optimizing processes, utilizing advanced technologies, and fostering a culture of efficiency, specialized shops can deliver these projects on time, ensuring satisfied customers who rely on their vehicles for both daily use and passion-driven pursuits.

Optimizing Engine Rebuild Processes

In the fast-paced world of automotive restoration, optimizing engine rebuild processes is key to achieving swift turnarounds without compromising quality. Select Engine Rebuilds focuses on streamlining every step, from meticulous disassembly to precise reassembly, ensuring a seamless and efficient workflow. By employing advanced diagnostic tools for accurate engine diagnostics and repairs, they identify potential issues early, eliminating time-consuming troubleshooting later.

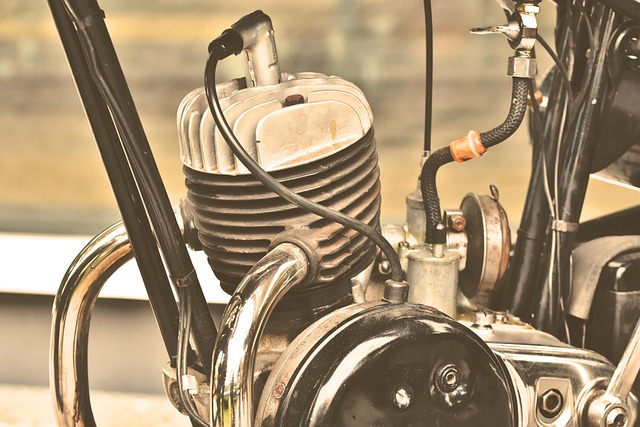

This strategic approach includes selecting the right parts for each unique rebuild project, catering to all makes and models. Whether it’s rebuilding motorcycle engines or tackling complex car engine overhauls, their expertise lies in balancing speed with meticulous craftsmanship. This dedication to optimizing processes empowers Select Engine Rebuilds to deliver high-performance, reliable engines, satisfying customers who value both timely service and top-notch quality in engine rebuilding for all makes.

Tools and Techniques for Efficient Build Times

In the realm of select engine rebuilds, mastering tools and techniques is key to achieving fast turnaround times. One of the primary strategies involves streamlining the disassembly process, ensuring every component is carefully documented and organized for efficient reassembly. Advanced diagnostic tools, such as computer-aided design (CAD) software and 3D printing, play a pivotal role in precision engineering, enabling faster manufacturing of custom parts. Additionally, implementing lean manufacturing principles helps eliminate unnecessary steps, reducing engine noise and enhancing overall efficiency.

Expert engine reconditioning professionals leverage specialized machinery and precise measurement tools to ensure each rebuild meets the highest standards. Affordability doesn’t have to compromise quality; efficient engine modifications tailored to specific needs can significantly reduce build times without sacrificing performance. These techniques, combined with a meticulous approach, result in exceptional engine performance upgrades, transforming old engines into powerful, reliable workhorses.

In today’s competitive automotive landscape, swift engine rebuild turnaround times are essential for Select Engine Rebuilds to meet customer demands. By optimizing processes and employing efficient tools and techniques, these specialized shops can significantly reduce build times without compromising quality. This approach ensures that vehicle owners receive their restored engines promptly, enhancing overall satisfaction with the service.